-

Envíenos un correo electrónico

sale@lscmagnetics.com -

Número de contacto

+86 -13559234186

Envíenos un correo electrónico

sale@lscmagnetics.com

Número de contacto

+86 -13559234186

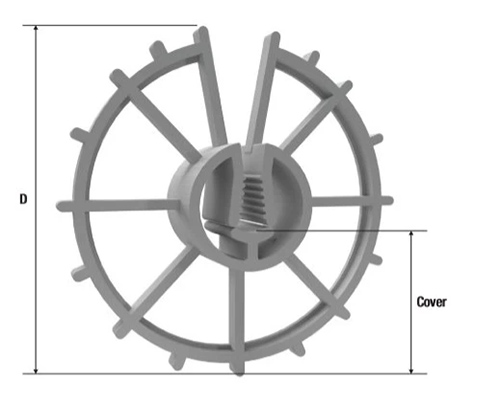

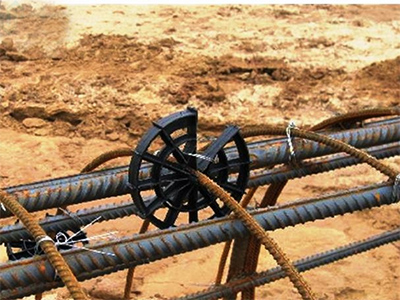

Las ruedas espaciadoras de varillas de refuerzo son un tipo de soporte plástico diseñado para hormigón prefabricado que se utiliza para fijar la posición de las varillas y mantener la distancia entre estas y el encofrado. Su función principal es asegurar un espesor uniforme de la cubierta de hormigón después del vertido y evitar el riesgo de corrosión causado por varillas expuestas o insuficientemente cubiertas15. Este tipo de producto suele estar fabricado con plástico de alta resistencia (como PA o HDPE), resistente a la corrosión, a altas temperaturas y al envejecimiento, y es adecuado para muros verticales, forjados horizontales y estructuras complejas.

Número de artículo :

Rebar Spacer Wheels For Precast ConcreteOrden (MOQ) :

5000Origen del producto :

chinaPlazo de entrega :

7-10daysRuedas espaciadoras de varillas de refuerzo para hormigón prefabricado

En la construcción de hormigón prefabricado, asegurar la colocación precisa de las barras de acero y un espesor uniforme de la cubierta de hormigón es clave para garantizar la durabilidad y la seguridad del edificio. Como herramienta de soporte eficiente, las ruedas espaciadoras de varillas de refuerzo se están convirtiendo gradualmente en un estándar en la industria.

Características

Material duradero: generalmente hecho de plástico duradero no corrosivo, puede resistir la corrosión química y tiene una larga vida útil.

Fácil de instalar: diseño simple, instalación rápida, sin necesidad de utilizar alambre de unión, la barra de acero se puede insertar directamente en la posición fija de la rueda.

Ligero y fácil de usar: liviano, fácil de transportar y operar, adecuado para usar en sitios de construcción.

Amplia gama de aplicaciones: compatible con varios diámetros de barras de acero, adecuado para componentes de hormigón prefabricado de diferentes tamaños y formas.

Tipos comunes

Rueda espaciadora ordinaria: adecuada para posicionar el espaciado de barras de acero en componentes de hormigón prefabricado en general.

Rueda espaciadora bloqueada: con función de bloqueo, puede fijar mejor las barras de acero y evitar que se aflojen durante el vertido del hormigón.

Rueda espaciadora de pilotes perforados: se utiliza especialmente para posicionar la jaula de acero en la construcción de pilotes perforados.

Especificación

| ||||

| No. | Tamaño de la varilla de refuerzo | Cubierta/Tamaño | D | Cantidad/caja |

| LSC058 | Varilla de refuerzo n.° 3-n.° 4 | 5/8'' | 1-7/8'' | 1800 |

| LSC1 | Varilla de refuerzo n.° 3-n.° 5 | 1'' | 2-5/8'' | 900 |

| LSC112 | Varilla de refuerzo n.° 3-n.° 6 | 1-1/2'' | 3-5/8'' | 700 |

| LSC2 | Varilla de refuerzo n.° 3-n.° 6 | 2'' | 4-5/8'' | 450 |

| LSC2 | Varilla de refuerzo n.° 3-n.° 6 | 3'' | 5-5/8'' | 270 |

| LSC312 | Varilla de refuerzo n.° 3-n.° 6 | 3-1/2'' | 6-5/8'' | 200 |

Usos

Mantenimiento de la separación entre las barras de acero: En los componentes de hormigón prefabricado, las barras de acero deben mantener una separación adecuada para garantizar la uniformidad de la tensión y la estabilidad estructural del hormigón. Las ruedas espaciadoras de barras de refuerzo fijan las barras de acero en la posición correcta para evitar que se desplacen durante el vertido del hormigón.

Proporcionar una capa protectora para el hormigón: asegúrese de que haya suficiente espesor de capa protectora entre las barras de acero y la superficie del hormigón para evitar que las barras de acero queden expuestas al aire, evitando así la corrosión de las barras de acero.

Aplicable a una variedad de componentes prefabricados: se puede utilizar para colocar las barras de acero de paneles de pared prefabricados, columnas, vigas, losas de piso y otros componentes.

¿Cómo prolongar eficazmente la vida útil de las ruedas espaciadoras de barras de refuerzo?

Limpieza y mantenimiento: Limpie las ruedas espaciadoras de varillas de refuerzo regularmente, según la limpieza del entorno de uso. Limpie la superficie con un paño seco y sin aceite, y evite el uso de productos químicos altamente corrosivos. Para las ruedas espaciadoras metálicas, se pueden utilizar desoxidantes especiales o recubrimientos anticorrosivos.

Revise los sujetadores: verifique periódicamente si las piezas de conexión de la rueda espaciadora están flojas, incluidos pernos, tuercas, etc. Utilice herramientas apropiadas (como llaves) para las operaciones de ajuste para evitar daños causados por una fuerza excesiva.

Tratamiento anticorrosivo: Seleccione un ciclo anticorrosivo adecuado según la corrosividad del entorno de uso. Antes de aplicar el tratamiento anticorrosivo, asegúrese de que la superficie de la rueda espaciadora esté limpia y libre de aceite, y siga las instrucciones del fabricante.

Mantenimiento de la lubricación: Si la rueda espaciadora contiene piezas deslizantes o giratorias, estas deben lubricarse regularmente para reducir el desgaste. Generalmente, se recomienda realizar una lubricación completa trimestralmente.

Solución de problemas: los problemas comunes que pueden ocurrir durante el uso incluyen aflojamiento, deformación o corrosión de la rueda espaciadora.

ETIQUETAS :