-

Envíenos un correo electrónico

sale@lscmagnetics.com -

Número de contacto

+86 -13559234186

Envíenos un correo electrónico

sale@lscmagnetics.com

Número de contacto

+86 -13559234186

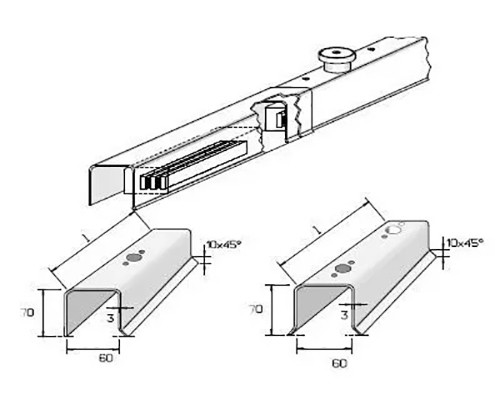

Sistema de trabajo magnético U60: una solución revolucionaria para la producción de paneles prefabricados y paredes dobles

Mar 12, 2025En los proyectos de construcción modernos, la eficiencia de producción y la calidad de los paneles prefabricados y los paneles de doble pared afectan directamente el progreso y el costo del proyecto. Para enfrentar este desafío, el sistema de trabajo magnético U60 surgió. Esta tecnología innovadora no solo simplifica el proceso de construcción, sino que también mejora en gran medida la precisión y la fortaleza de los componentes del edificio.

¿Qué es el Sistema de trabajo magnético U60?

El sistema de forma magnética U60 es un sistema de formulario basado en tecnología magnética, específicamente diseñado para la producción de paneles prefabricados y paneles de doble pared. Correge el formulario al marco de acero a través de una fuerte fuerza magnética, reemplazando el perno tradicional o el método de fijación mecánica. Este sistema no solo es más fácil de instalar y eliminar, sino que también garantiza la estabilidad y la precisión del formulario al verter concreto.

El núcleo del sistema de trabajo magnético U60 se encuentra en su dispositivo magnético único, que puede absorber y liberar rápidamente el formulario, reduciendo en gran medida el tiempo y la complejidad de la operación manual. Además, el sistema es adecuado para la producción de una variedad de componentes de concreto, que incluyen losas de piso, paneles de pared, vigas y columnas, etc., y tiene una amplia gama de aplicabilidad.

Ventajas técnicas del sistema de trabajo magnético U60

1. Instalación y desmontaje eficientes

Los sistemas de forma tradicionales generalmente requieren una gran cantidad de pernos y fijación mecánica, y el proceso de instalación y desmontaje es engorroso y requiere mucho tiempo. El sistema de trabajo magnético U60 utiliza adsorción magnética, y solo las operaciones simples pueden completar la fijación y la liberación del formulario, lo que mejora significativamente la eficiencia de la construcción.

2. Alta precisión y estabilidad

La adsorción magnética garantiza un ajuste cercano entre el formulario y el marco de acero, evitando los problemas de aflojamiento o desalineación que pueden ocurrir en los métodos de fijación tradicionales. Este método de fijación de alta precisión hace que el tamaño y la forma de los componentes de concreto sean más precisos y reduce la carga de trabajo de la finalización posterior.

3. Reducir los costos laborales

Debido a la operación simple del sistema de trabajo magnético U60, reduce la dependencia de los trabajadores calificados y reduce los costos laborales. Al mismo tiempo, el sistema tiene un alto grado de automatización, lo que reduce aún más los errores en la operación manual.

4. Protección y sostenibilidad del medio ambiente

El sistema de trabajo magnético U60 utiliza Forma de acero reutilizable, que reduce el uso de materiales de forma tradicionales como la madera, en línea con el concepto de construcción ecológica y desarrollo sostenible. Además, la larga vida y el bajo costo de mantenimiento del sistema también lo convierten en una elección rentable.

5. Fuerte adaptabilidad

El sistema de forma magnética U60 es adecuado para la producción de una variedad de componentes concretos y puede satisfacer las necesidades de diferentes proyectos de ingeniería. Ya sea que se trate de un gran edificio comercial o un proyecto de infraestructura, el sistema puede proporcionar una solución confiable.

El sistema de trabajo magnético U60 se ha utilizado ampliamente en muchos proyectos de ingeniería importantes debido a su excelente rendimiento.

1. Edificios de gran altura: en la construcción de edificios de gran altura, el uso de paneles prefabricados y paneles de pared doble pueden acortar significativamente el período de construcción. La eficiencia y precisión del sistema de forma magnética U60 lo convierte en una opción ideal para proyectos de construcción de gran altura.

2. Ingeniería de puentes: la ingeniería del puente requiere una precisión y resistencia extremadamente altas de los componentes de concreto. El sistema de trabajo magnético U60 se ha utilizado en muchos proyectos de puentes grandes para garantizar la calidad de los componentes y el progreso de la construcción.

3. Ingeniería de metro y túnel: la ingeniería de metro y túnel generalmente requiere una construcción rápida en un espacio limitado. La conveniencia y la eficiencia del sistema de forma magnética U60 lo convierten en la primera opción para tales proyectos.

ETIQUETAS :