-

Envíenos un correo electrónico

sale@lscmagnetics.com -

Número de contacto

+86 -13559234186

Envíenos un correo electrónico

sale@lscmagnetics.com

Número de contacto

+86 -13559234186

¿Qué tan efectiva es la adsorción de limaduras de hierro en barras magnéticas fuertes en la producción de nuevos materiales energéticos?

Jul 09, 2025

En la producción de nuevos materiales energéticos, las fuertes varillas de eliminación de hierro magnéticas demuestran un excelente rendimiento en la adsorción de limaduras finas de hierro, lo que se refleja principalmente en los siguientes aspectos:

1. Alta intensidad del campo magnético

Las varillas magnéticas de alta potencia para la eliminación de hierro suelen estar fabricadas con materiales magnéticos permanentes de neodimio-hierro-boro (NdFeB) de alto rendimiento. Estos materiales poseen una energía magnética y una coercitividad extremadamente altas, capaces de generar una intensidad de campo magnético de hasta 12 000-16 000 Gauss. Bajo un campo magnético tan potente, incluso las limaduras de hierro finas, con diámetros de tan solo unos pocos micrómetros, son atraídas por la intensa fuerza magnética y se adsorben en la superficie de la varilla magnética. Los datos experimentales muestran que, en un entorno de campo magnético de 13 000 Gauss, la fuerza de adsorción de una varilla magnética fuerte Las partículas de hierro de 5 μm pueden superar 1.000 veces su propio peso.

2. Diseño estructural optimizado

El diseño estructural de las varillas magnéticas de alta potencia mejora aún más su capacidad para adsorber limaduras finas de hierro. Las varillas magnéticas con una estructura magnética multicapa pueden aumentar eficazmente el gradiente del campo magnético, mejorando así el efecto de adsorción sobre las limaduras finas de hierro. La capa exterior de los imanes de baja coercitividad adsorbe primero las limaduras de hierro más grandes, mientras que la capa interior de los imanes de alta coercitividad se encarga de capturar las limaduras más finas. Este diseño puede aumentar la eficiencia de adsorción de limaduras de hierro menores de 1 μm en aproximadamente un 20 %. Además, las varillas magnéticas más delgadas pueden producir un campo magnético más concentrado, lo cual resulta más ventajoso para la adsorción de limaduras finas de hierro.

3. Efectos de aplicación práctica

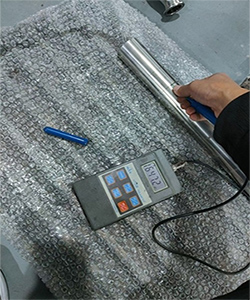

La aplicación de varillas magnéticas potentes en la producción de nuevos materiales energéticos ha mostrado resultados significativos. Por ejemplo, en el proceso de producción de materiales de ánodo de silicio-carbono, al disponer varillas magnéticas potentes en la tubería de transporte de material para formar un dispositivo de desferrización, se pueden adsorber eficazmente las virutas finas de hierro en las materias primas, reduciendo el contenido de impurezas de hierro de 20 ppm iniciales a menos de 5 ppm. En el proceso de molienda de materiales de cátodo de fosfato de hierro y litio, el uso de una varilla magnética potente con un diámetro de 10 mm, combinada con un diseño de circuito magnético adecuado, puede lograr una intensidad de campo magnético en la superficie de la varilla magnética de más de 13 000 Gauss, adsorbiendo eficazmente las virutas finas de hierro generadas durante el proceso de molienda.

4. Tratamiento y mantenimiento de superficies

El tratamiento superficial de las varillas magnéticas de alta potencia es igualmente importante. Para evitar la corrosión durante el uso y evitar dificultades al limpiar las limaduras de hierro adsorbidas, su superficie suele recibir un tratamiento especial, como una funda de acero inoxidable o un plástico apto para uso alimentario. Este tratamiento superficial no afecta el rendimiento magnético de la varilla, pero puede prolongar su vida útil y garantizar que su capacidad para adsorber limaduras de hierro finas se mantenga estable a largo plazo. La limpieza y el mantenimiento regulares de la varilla magnética de alta potencia también son cruciales. Mediante un mantenimiento adecuado, la varilla magnética puede mantener un buen rendimiento de adsorción de forma continua.