-

Envíenos un correo electrónico

sale@lscmagnetics.com -

Número de contacto

+86 -13559234186

Envíenos un correo electrónico

sale@lscmagnetics.com

Número de contacto

+86 -13559234186

¿Cómo seleccionar un sistema de elevación y anclaje adecuado para componentes prefabricados pesados?

Nov 26, 2025En la actual construcción industrializada y los proyectos de infraestructura a gran escala, en rápido desarrollo, el uso de componentes prefabricados pesados (como losas doble T pretensadas, vigas de gran luz, paneles de muro gigantes y módulos de energía nuclear) se ha vuelto común. Estos han supuesto un salto en la eficiencia de la construcción y un alto grado de control sobre la calidad del proyecto. Sin embargo, cada movimiento de estos gigantes, especialmente durante la elevación, afecta la seguridad de todo el proyecto.

El sistema de anclaje de elevación Es el eslabón más crítico de esta cadena de seguridad. Una selección incorrecta puede provocar daños en los componentes y retrasos en el proyecto, o incluso accidentes catastróficos. Por lo tanto, ante la impresionante variedad de productos de anclaje disponibles en el mercado y las complejas condiciones de trabajo, ¿cómo podemos tomar una decisión científica, segura y económica?

Antes de hacer una selección, debemos ser quienes mejor conocemos el componente. La información clave incluye:

1. Peso del componente y centro de gravedad: Este es el dato más crucial. No solo se debe conocer el peso total, sino que también se debe definir claramente la ubicación del centro de gravedad mediante los planos de diseño para garantizar una tensión equilibrada durante la elevación y evitar vuelcos.

2. Resistencia del hormigón: La capacidad de carga del sistema de anclaje está directamente relacionada con la resistencia del hormigón. La resistencia inicial (resistencia al desmoldeo) y la resistencia de diseño del componente en el momento del izado deben estar claramente definidas.

3. Tamaño y forma del componente: ¿Se trata de una viga esbelta, una losa ancha o un componente de forma irregular? Esto determina las posibilidades y el número de puntos de izado.

4. Distribución del refuerzo: Los anclajes deben coexistir armoniosamente con la malla de refuerzo interna del componente para evitar conflictos. Es fundamental contar con planos detallados de la disposición del refuerzo.

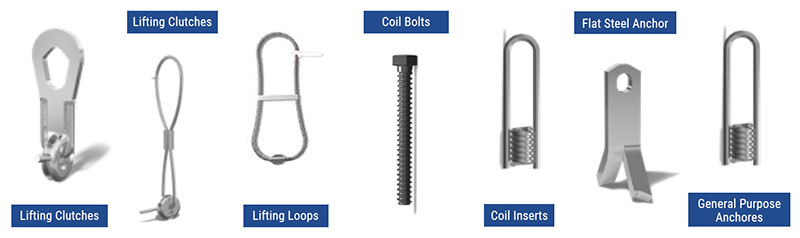

Los métodos comunes de elevación y anclaje incluyen los siguientes:

(I) Anclaje con piezas empotradas

Las piezas empotradas son uno de los métodos de anclaje más comunes para el izado de componentes prefabricados. Las propiedades del material y los cálculos de construcción de las piezas empotradas deben cumplir con las disposiciones de las normas nacionales vigentes. Durante la producción de componentes prefabricados, los anclajes deben empotrarse con precisión según los requisitos de diseño para garantizar que su posición y cantidad satisfagan las necesidades de izado. La capacidad portante de las piezas empotradas debe calcularse rigurosamente para cumplir con los requisitos de tensión en diversas condiciones de trabajo durante el izado. Por ejemplo, al fijar grúas torre, soportes temporales y otros equipos a componentes prefabricados, las piezas empotradas deben ajustarse según los cálculos de tensión.

(II) Anclaje con pernos pasantes

Para algunos componentes de muro prefabricados, se pueden utilizar pernos pasantes para el anclaje. Durante la producción de componentes prefabricados, se deben reservar los orificios pasantes y diseñar las medidas de refuerzo pertinentes en esta ubicación. El diámetro y la posición de los orificios de los pernos pasantes deben ajustarse estrictamente a los requisitos de diseño para garantizar la fiabilidad del anclaje.

(III) Anclaje con tuercas o pernos empotrados

Las tuercas o pernos embutidos son otro método de anclaje común. Las ventajas de este método son la comodidad de elevación y la posibilidad de seleccionar el método adecuado según las normas del producto. Durante la prefabricación de componentes, se preincrustan tuercas o pernos embutidos en ellos, lo que garantiza un posicionamiento preciso. Durante la elevación, una herramienta especial conectada al equipo de elevación trabaja en conjunto con las tuercas o pernos embutidos para lograr una elevación estable de los componentes.

Para hacer coincidir la información del componente con el tipo de anclaje es necesario realizar una evaluación sistemática de los cinco puntos siguientes:

1. Capacidad de carga y factor de seguridad

* Línea Roja Absoluta: La carga de trabajo nominal del sistema de anclaje debe ser mayor que el peso del componente que soporta.

* Efectos dinámicos: El factor dinámico durante la elevación (normalmente entre 1,5 y 2,5, o incluso mayor) debe tenerse en cuenta al calcular la carga de diseño.

* Factor de seguridad: Seleccione productos certificados con un alto factor de seguridad (normalmente ≥4:1 o 5:1). Nunca utilice productos de baja calidad ni falsificados.

2. Modo de falla: el hormigón es clave

Un sistema de anclaje excelente está diseñado de modo que la fluencia del acero (barra de elevación o anclaje) preceda a la falla del hormigón. Esto significa que, en caso de sobrecarga, se observará una "advertencia" de deformación y elongación del acero, en lugar de la falla frágil causada por el colapso repentino del hormigón. Por lo tanto, es necesario realizar cálculos de falla del cono de hormigón.

3. Número y disposición de los puntos de elevación

* Principio básico: garantizar una elevación suave del componente y una distribución uniforme de la tensión en cada punto de elevación.

* Cantidad: Dependiendo del peso y la forma del componente, normalmente se requieren 2, 4 o más puntos de elevación.

* Disposición: La línea que conecta los puntos de elevación debe pasar por el centro de gravedad del componente, y el ángulo entre la línea y el plano horizontal (ángulo de la eslinga) no debe ser inferior a 60°. Cuanto menor sea el ángulo, mayor será la tensión en el punto de elevación.

4. Facilidad de instalación y repetibilidad:

* Desechables vs. Reutilizables: Los anclajes integrados suelen ser desechables, mientras que algunas herramientas de elevación especializadas son reutilizables, lo que requiere un análisis de costo-beneficio.

* Velocidad de instalación: En proyectos grandes, el anclaje rápido mejora significativamente la eficiencia.

5. Impacto a largo plazo en los componentes:

* Expuesto: Los manguitos roscados internos empotrados se pueden tapar después de la elevación, sin afectar la estética del edificio. Los anclajes expuestos pueden requerir cortes posteriores, lo que aumenta los procedimientos y los costos.

* Impacto en el desempeño estructural: Los anclajes empotrados no deben debilitar secciones críticas del componente ni interferir con los tendones de pretensado.

Seleccionar un sistema de izado y anclaje para componentes prefabricados pesados no es simplemente elegir el que mejor se vea, sino un proceso de ingeniería riguroso y sistemático. Requiere comenzar con las características de los componentes, comprender a fondo los principios de los distintos métodos de anclaje y realizar una evaluación exhaustiva basada en los principios de seguridad, economía y eficiencia.

Recuerde, el sistema de izado y anclaje es el cable que conecta lo "estacionario" con lo "móvil". Invertir un esfuerzo extra en él es la mejor garantía para el buen desarrollo de todo el proyecto y la seguridad de todos los involucrados.

ETIQUETAS :